Top 5 Collision Repair Mistakes & How ADAS Calibration Prevents Comebacks

Modern cars are more advanced than ever. They come equipped with sensors and ADAS features that require precision after a crash. A single overlooked detail can cause safety issues or lead to a comeback job. These jobs are not only expensive but also damage a shop’s reputation. Mistakes like skipped calibrations or incomplete diagnostics are more common than they should be. The need for accurate post-collision diagnostics and calibrations continues to grow. ADAS use is projected to nearly double in the next five years (CCC Trends, 2024).

Missed ADAS Calibrations:

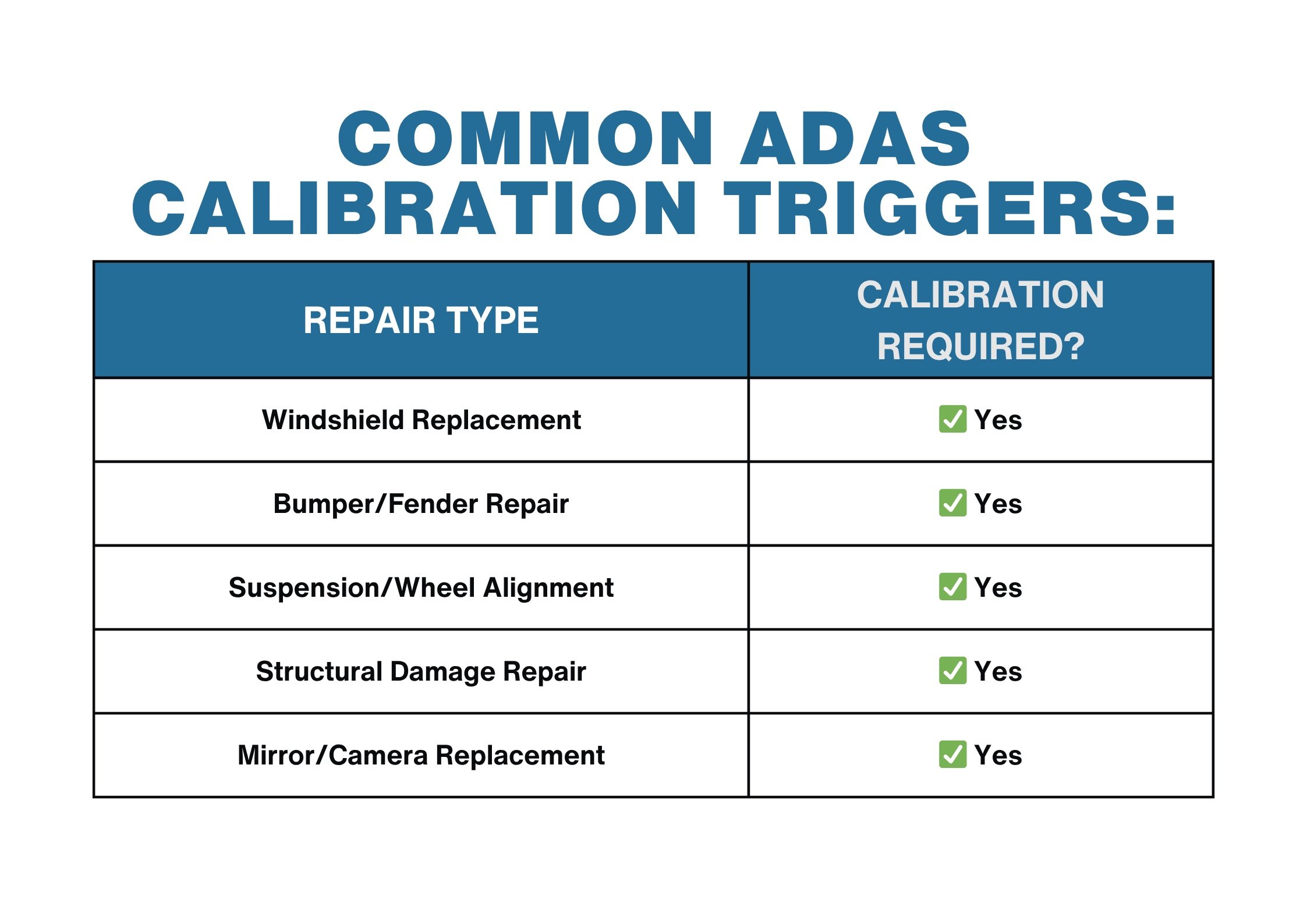

Many shops still skip required ADAS calibrations. An estimated 88% of necessary calibrations go unperformed. This means many repaired vehicles may have safety systems that fail to function. Features like lane-keep assist and emergency braking rely on exact calibration. Just a one-degree misalignment can cause a complete system failure (Collision Repair Magazine, 2021). For example, even a sensor 1mm off can lead to errors. Common calibration triggers include windshield replacement, body panel damage, and alignment. These systems must be tested and adjusted properly after repair.

How to prevent it:

Check if the vehicle has ADAS before writing an estimate. Consult OEM procedures for calibration requirements. Build calibration into your repair process and schedule. Partner with a trusted calibration provider when needed. Skipping calibration now can result in expensive rework later.

2. Incomplete Pre- and Post-Repair Scans

Many shops skip or partially complete diagnostic scans. These scans detect hidden issues not visible to the eye. Trouble codes do not always trigger dashboard lights. A pre-repair scan helps build an accurate estimate. A post-repair scan confirms that all repairs are complete. Clearing DTCs without fixing the issue is another common error (I-CAR, 2018). Some faults only show up after a test drive. Generic scanners may not access all ADAS systems. OEM scan tools or verified alternatives are crucial (Repairer Driven News, 2025).

How to prevent it

Always scan before and after every repair. Use scan tools approved for the specific make and model. Save and document scan results in the job file. Perform a road test after repair when required. Scans help catch problems early, before a comeback happens.

3. Improper Sensor Mounting or Alignment

Even if calibration is performed, incorrect mounting can still cause problems. Sensors are very sensitive to small changes. A camera or radar that is one degree off may cause system failure (Collision Repair Magazine, 2021). Improper torque, bent brackets, or reused hardware often lead to misalignment. Some errors do not trigger any codes. A system might look fine but operate incorrectly. Painting over sensors can also reduce performance.

How to prevent it

Always follow OEM repair instructions when installing or remounting sensors. Replace brackets if bent or damaged. Use the right tools to align and aim sensors. Perform calibration in a controlled environment. Never rely on visual judgment alone.

4. Ignoring OEM Repair Procedures

Shops sometimes skip OEM repair procedures due to time or habit. This leads to missing steps or improper parts use. OEMs provide detailed instructions for each vehicle and repair. Ignoring these procedures can compromise safety. A study found that 80% of shops do not consult OEM guidelines on every repair (GM Study, 2020). Failure to follow OEM guidance increases liability. Courts may view "recommended" steps as required during litigation (Greco Publishing, 2022).

How to prevent it

Access OEM repair manuals for every job. Build time into the estimate for repair research. Train staff on reading and applying OEM procedures. Save relevant pages in the job file. Follow OEM instructions precisely. This protects both the shop and the guest.

5. Poor Documentation and Repair Records

Missing or vague documentation creates problems when issues arise. Without detailed records, shops cannot prove proper repairs were completed. Poor documentation includes missing photos, scan reports, and calibration results. It also includes skipped checklist sign-offs. Lack of proof can result in liability or warranty disputes. Quality control checklists can catch errors early (I-CAR, 2014).

How to prevent it

Document every step of the repair. Save scan and calibration reports. Use photos before and after key steps. Implement a sign-off checklist. Have managers review repairs before delivery. Good records help resolve disputes and avoid comebacks.

Prevent Comebacks with Abel Diagnostic Centers

As cars grow more complex, repairs require advanced tools and training. Abel Diagnostic Centers supports body shops with post-collision diagnostics and calibration. Our team offers same-day service, OE-compliant tools, and photo documentation. We help shops verify repairs before delivery. Partnering with Abel reduces liability, saves time, and protects your reputation.

Here’s how Abel Diagnostic Centers provides targeted services that help prevent the top 5 repair mistakes:

Collision ADAS Recalibration: We recalibrate ADAS sensors after structural repairs, panel replacements, and windshield installs to restore system accuracy.

ADAS Diagnostics: Our team performs deep-dive diagnostics using OE-compliant tools to identify hidden codes and verify system integrity.

ADAS Recalibration: We provide static and dynamic recalibrations for radar, cameras, LIDAR, and parking sensors in controlled conditions.

ADAS Calibration: All calibrations are performed following OEM specs using certified targets, level flooring, and correct lighting.

Sensor Calibration: We inspect, mount, and recalibrate misaligned or replaced sensors affected during collision repair.

ADAS Module Programming: Our team performs safe and accurate programming of ADAS modules, restoring features like blind spot monitoring or auto braking.

Each service supports your team in delivering safe, complete, and verifiable repairs. With Abel, you can prevent costly rework and confidently return vehicles with fully functioning safety systems.

Each service is designed to complement your repair workflow and catch common oversights before a vehicle is returned to the guest. Abel helps reduce rework, increase trust, and support compliance with manufacturer and insurer requirements.

Source:

“Who Pays for What?” Quarterly Survey by Collision Advice & CRASH Network (2023 Edition)

📎 Who Pays for What? Survey – 2023 Summary

Note: Requires email registration for full report PDF.